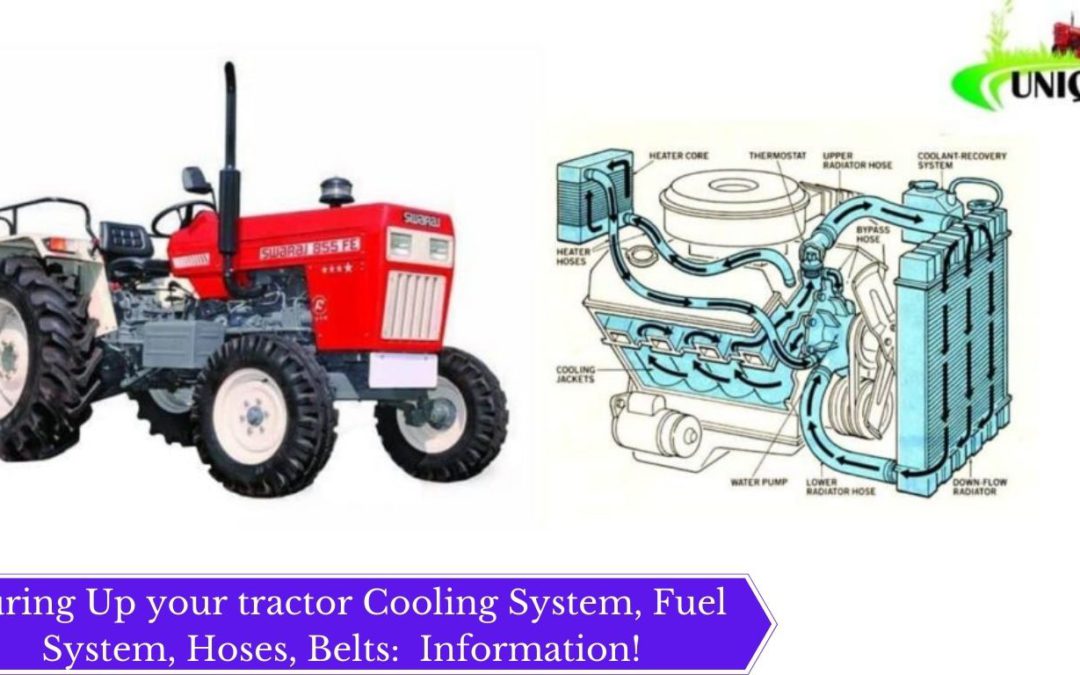

In this blog here we discuss about how you can turn up your tractor cooling system, fuel system, hoses, belts. The old oil, tractor cooling system and filter have been taken to the recycler and the air filter substitution has inhaled new life into our engine. Presently take a gander at the tractor cooling system since it needs to work hard in the summer heat. Tractor Cooling system can be genuine peevish in their old age. Radiator centers stop up with rust, lime, or other mineral stores and the fins clog up with weed seeds and debris. The metal headers gradually erode from long periods of use and the creases appear to consistently be soggy with lingering antifreeze. On hot days the radiator cap roars out a surge of steam and helps one to remember an old model T close by the street with an overheated engine.

Note- You may also check that how you can turn up your tractor oil filter.

We have two brand names under the banner of “Unique Auto Products Pvt. Ltd”. The former brand name is known as “Unique” and the latter brand name is known as “Geeken”. Under the brand name of “Unique”, we provide all “Tractor spare parts”.

The radiator, for the most part at the front of the tractor, is a decent spot to begin. Check the front and back for the development of bugs, seeds, and weeds from the field. Water from a garden hose showered from the fan side of the radiator will eliminate a great deal of the developed garbage. Next check for moisture around the radiator center and headers. If there is a leakage, it will be damp and smell sweet. If there is a leakage, it is shrewd to have the radiator expertly stream tried and checked for lime development and center leakage. Then, eliminate the radiator cover and review its base.

The cap is intended to bring the pressing factor up in the tractor cooling system so the coolant bubbles at a higher temperature. Each pound of pressing factor raises the limit by 3 degrees. A six-pound pressure cap would raise the limit of the coolant by eighteen degrees, or from 212 degrees to 230 degrees. Ensure and check the manual for the legitimate pressing factor cap as one that is too high tends to blow hoses and radiator centers.

If you need “Tractors spare parts”, then you can mail us at [email protected].

The lower part of the cap ought to be perfect and should fit onto the filler neck. Check the rubber base for expansion, scratches, or breaks. Additionally, check the brass filler neck for consistency on the fixing surfaces. A warp or hairline break will make pressure spill out when being used.

- Before proceeding with our antifreeze investigation, it is insightful to check all the tractor cooling system hoses. Hoses that are hard, weak, or broken should be supplanted. On different hoses search for little fixes of dampness on the hose surface and afterward delicately manipulate that region and chase for a hairline break or pinhole. These zones will in general release just when the tractor is at working temperature and under tension and can be hard to take note of.

“Unique Auto Products Pvt. Ltd” deals in all types of “Tractor spare parts”. Visit https://uniqueautoproducts.in/ for more info.

While spilling, however, they can shoot a hair-sized stream of hot antifreeze onto electrical parts and cause the engine to fail. Search for hoses that must expand due to oil tainting. They feel oily and light when manipulated. Supplant any hoses that are minimal.

- It’s acceptable to change the hose cinches additionally as soil and coarseness can make them hard to appropriately force. Likewise, ensure and buy the right hose size. A hose that is too enormous or too little will just motivation issues sometime in the not-too-distant future, particularly if a fixing compound like silicone is utilized to attempt to water fix connection.

Antifreeze, these days, is a combination of ethylene glycol and water. It used to be a blend of ethyl or methyl liquor and water. With mechanical advances and distinctive fixing compounds alongside higher engine temperatures, the liquor blend got out of date as it would vanish or not give satisfactory inward part security in customary use. However, freezing assurance the arrangement gives a synthetic soup of inner engine defenders.

- It contains a rust-retardant, molecule suspension compounds, grease for the water siphon seals and bushings, and erosion resistors. At the point when this substance intensifies destroy the antifreeze will change the tone and additionally get overcast. A corroded antifreeze tone, for instance, implies that the rust inhibitor has carried on with its valuable life. Look at the shade of the antifreeze compound in the unit you are examining.

- It should be spotless and green. Take a temperature analyzer and see what the edge of freezing over is. If the antifreeze has been in the unit for over three years, it is a smart thought to supplant it. Changing the stuff isn’t that huge an arrangement.

- Filter the radiator substance into a compartment. Make a point not to spill any because the canine will adore the sweet taste yet it is exceptionally harmful whenever ingested. Likewise, discover the filter cockerel on the engine and filter an additional couple of quarts out of the square. Refixes the square filter and top off the radiator with new antifreeze and, ideally, refined water.

Time to check the belts on the engine. Most tractors will just have one, and no more two belts. They typically run the fan/water pump gathering and generator. Grasp each drive belt and move it around with the goal that the base and one side are noticeable. Search for indications of breaking, soil soaking, hard-coated contact surface, parting, or fraying. Supplant any belt giving these indications. Ensure when putting in new belts or while retightening old ones to get the right belt strain.

Our team of hardworking employees is working round the clock to provide you “Tractor spare parts” at any time. For more information, you can call us at the following number “9643811015”.

- The last good to check is the fuel filter. This frequently ignored thing can make no closure an engine running funny. At the point when stopped it will lean out the fuel combination and cause exploded backward, spitting, and failing.

At the point when the engine passes on back pressing factor from growing fume from the fuel, it will push trash from the filter once more into the tank and let fuel stream unreservedly for a little bit.

- The engine will fire up and run like ordinary until trash, indeed, discovers its way back into the filter component.

It is an easy thing. Additionally, check the fuel hoses, if rubber, for crimping, squeezing from tight twists, or inside expanding because of utilizing a hose that is non-viable with gas. Likewise, verify whether a fuel line is running close to a ventilation system or line. The additional warmth will at times cause a disintegrating issue on hot days where the fuel will go to a gas in the line and cause the fuel circuit to ‘fume lock’, or quit conveying fuel to the carb. If this happens a wrapping of aluminium foil around the fuel line and appended with bread twisties will mirror the emanated warmth and help alleviate the issue.

We are fully committed towards the complete satisfaction of our customers. With excellent service quality and an unmatched professional devotion, we have earned the reputation of being one of the best suppliers of “Sonalika ractor spare parts”. So if you want to purchase spare parts of any kind of tractor, we are only a call away.

Related Links

Top 10 famous Massey Ferguson Tractors: Features & Prices

Top 10 Swaraj Tractor Models : List, Features And Price