Contents

In this blog we will discuss about the kinds of excavators its uses and features. Excavators are construction equipment with the capacity to move about on several types of terrain and move in 360 degrees. Excavators use a pressure-driven system to lift things, scoop up dirt, and burrow. Most of the time excavators are found on mining sites, demolition, or digging trenches. The size of this equipment varies from smaller than normal excavators to the size of a mining excavator. Choosing which excavator will work for your construction organization is significant. You may also check the difference between backhoe and excavator.

We have two brand names under the banner of “Unique Auto Products Pvt. Ltd”. The former brand name known as “Unique” and the latter brand name known as “Geeken”. Under the brand name of “Unique”, we provide all “Mahindra, Sonalika , John Deere, New Holland & Massey Ferguson Tractor spare parts”.

Tips for choosing an excavator:-

Terrain:

It is essential to know the sort of landscape you will be working with. For instance, if you live in rough terrain, it is hard to get a bigger excavator to some construction sites whereas if you will work in a clearing you are likely going to have the option to use the bigger excavators if necessary.

The sort of dirt you will work in is important. It is easy to get an excavator stuck in the mud when it several tons.

If you need “Tractors spare parts”, then you can mail us at [email protected].

Transportation:

Excavators expect trailers to transport them from job site to place of work. The bigger the machine the bigger the trailer. You may have to have a wide load trailer to transport the equipment.

- Remember that unless the places of work are close most excavators don’t go more than 20 miles an hour and it will require hours to transport them without a trailer. This can be a genuine worry for fuel and transportation costs.

Size:

Mini excavators function admirably for those sites you can’t get a large machine into and those that don’t need a large hole or much lifting. Smaller than usual excavators are frequently best used for landscaping or foundations.

The bigger excavators that used as cranes, diggers, or in demolition are more proper for trenches and mining.

“Unique Auto Products Pvt. Ltd” deals in all types of “Mahindra, Sonalika , John Deere, New Holland & Massey Ferguson Tractor spare parts”. Visit https://uniqueautoproducts.in/ for more info.

Choosing the Correct Excavator for The Work

The best method to locate the correct excavator for a venture is to design. Knowing precisely what sort of job the excavator will play nearby will help figure out what sort of excavator required.

It is more proficient for something important to lease the correct size equipment for what required instead of attempting to make one-piece fit for a variety of jobs.

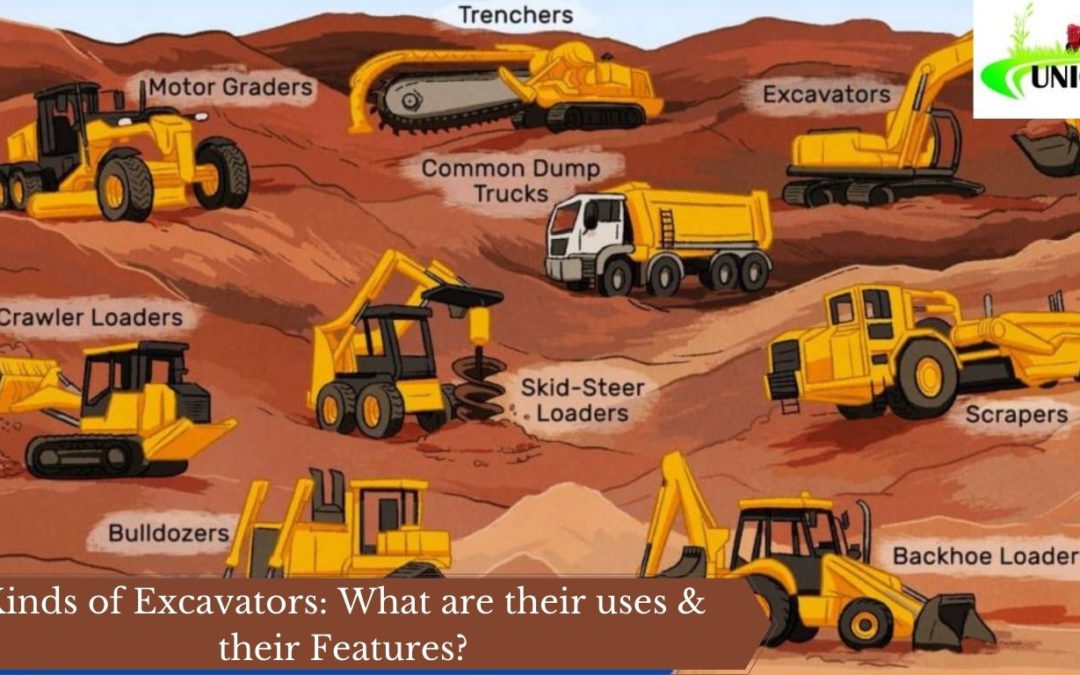

7 Kinds of Excavators

There are six key types of excavators accessible available: Crawler, Dragline, Suction, Skid Steer, Long Reach, Mini Excavator, and Wheeled Excavator.

Crawler Excavators:

Firstly, The most ordinarily perceived excavator used for mining, trench digging, and landscape evaluating the crawler excavator is the thing that most individuals picture when they hear “excavator”.

This sort of excavator is accessible on wheels instead of a track.

Dragline Excavators:

A bigger sort of excavator that uses a hoist rope and dragline system to clear earth for underwater projects, heap driving, or street excavations.

Suction Excavators:

Uses water jets and a high-pressure vacuum to clear earth, soil, and debris. Worked out of a wheeled vehicle the suction excavator used for underground applications, debris cleanup, and other fragile excavation projects.

Skid Steer Excavators:

A small machine with buckets that scoop away from the equipment cab is incredible for residential projects and small clearing tasks. They’re also just known as skid steer.

Long Reach at Excavators:

With arms that stretch out up to 100 feet with attachments, the excavator is useful for substantial digging and industrial demo projects.

Mini Excavator:

A minimized, smaller version of a crawler excavator, little excavators frequently alluded to as scaled-down diggers are useful in thin places of work, jobs with obstacles, and jobs with sensitive terrain like landscaping.

Wheeled Excavator:

The wheeled excavator is the same as a regular excavator however is fitted on wheels instead of tracks. Filling in acknowledgment for their use in city projects, wheeled excavators are getting increasingly mainstream.

Our team of hardworking employees is working round the clock to provide you “Mahindra, Sonalika , John Deere, New Holland & Massey Ferguson Tractor spare parts” at any time. For more information, you can call us at the following number “9643811015”.

4 key excavator safety basics any operator needs

The most significant safety highlight of any piece of hardware is, of course, the operator. To amplify excavator safety, the administrator should appropriately prepared both in working the machine and in safety procedures to prevent damage and injury.

Know Your Dangers Undercutting and Overloading

This occurs when the container used to dig the ground underneath the excavator’s tracks, increasing the probability of a cave-in.

- Proper excavator safety techniques direct that your excavator’s tracks should be opposite to the channel, in case of a cave-in. Another possible source of danger is over-burdening the basin.

Overloading can cause the excavator to spill or otherwise become unstable. Operators should ensure excavator safety by monitoring the heap limits for the machine.

Planning for Safety

To ensure proper excavator safety, the machine should have the option to work consistently, permitting the operator to dump an unstable burden in a crisis.

- Low fuel levels may mean the excavator will shut down startlingly, causing a potentially dangerous and unstable situation.

Moreover, A visual inspection of the machine before the operation is also a significant step toward excavator safety, as harm to the machine or other unsafe conditions might be visually clear.

Safety Around the Excavator Everybody’s Responsibility!

Remember that while digging with an excavator, nobody permitted in the trench while uncovering is occurring. What’s more, nobody permitted to be under the bucket whenever for any reason.

Members of the group acquainted with the excavator’s scope of movement and the work being done and should stay clear. This is a crucial piece of excavator safety.

Know Your Excavator’s Ability

- The lifting limit of the excavator can determined by consulting the load chart in the operator’s manual. Always know the limits of your excavator and never surpass the limit spread out in the load chart whenever, under any circumstances, regardless of whether you think you know better.

However, it essential to recollect that as a heap is lifted and moved away from the excavator, the machine’s lifting limit decreases. Know before you lift!

We fully committed towards the complete satisfaction of our customers. With excellent service quality and an unmatched professional devotion, we have earned the reputation of being one of the best suppliers of “Mahindra, Sonalika , John Deere, New Holland & Massey Ferguson Tractor spare parts”. So if you want to purchase spare parts of any kind of tractor, we are only a call away.

Related Links

Top 10 famous Massey Ferguson Tractors: Features & Prices

Top 10 Swaraj Tractor Models : List, Features And Price